The resulting inlet flow was 2.78 mL per minute. We used a 30 m x 0.25 mm ID x 0.25 µm df Rxi-5Sil MS (cat # 13623) with an initial oven temperature of 40 ☌ and employed a 30 psi pressure pulsed injection in a 275 ☌ inlet.

#RELATIVE RESPONSE FACTOR AGILENT MICRO GC FREE#

To calculate the splitless hold time, we used a free GC column pressure/flow calculator for Windows available from Agilent (Simply enter the column dimensions and instrument starting conditions as shown in Figure 1). Deactivated wool and liner surfaces help mitigate this, but once samples are being analyzed, the buildup of non-volatile co-extracted materials plays an increasingly significant role in adsorptive loss in the inlet. The high molecular weight compounds take a while to fully volatize and the acids and bases have a long residence time due to chemical adsorption onto the various surfaces in the inlet. This thorough inlet flush is especially important when performing semi-volatiles analysis.

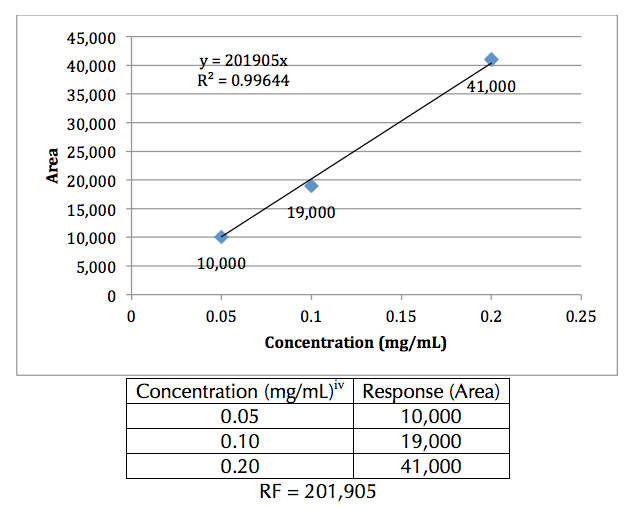

Ideally, you want to flush the inlet volume at least 1.5 times before opening the purge valve and evacuating residual solvent, which can impair the chromatography of early eluting compounds. This increases the raw response and enhances reproducibility, which is critical to achieving calibration linearity. Properly calculating the splitless hold time maximizes transfer of analytes to the column. Additionally, for the initial calibration (ICAL) as a whole to meet acceptance criteria, less than 10% of the individual compounds may have RSDs that exceed 20% and fail to meet the minimum R value for the alternative fit methods.Ĭorrect instrument settings are as important as an inert system when you are looking for linear and reproducible responses over a large calibration range. Failing this, one of the alternative fit methods described in EPA Method 8000 may be used, such as linear regression, provided that a minimum correlation coefficient (R) of 0.99 is achieved. The linearity requirements for individual compounds listed in EPA Method 8270D specify that the calibration is considered linear if the relative standard deviation (RSD) of the relative response factor (RRF) is less than 20%. The solution, however, may be much easier (and cheaper). Agilent wants you to buy a new inert source with a 6mm ID drawout plate. I’ve already done inlet maintenance.” Does this sound familiar? Maybe you’ve replaced your column too. “Help! My 8270 calibrations aren’t linear.

0 kommentar(er)

0 kommentar(er)